Since the cost of energy has dramatically increased during the past few years, it seems that energy audit companies have opened shop on more city street corners than coffee shops in Seattle.

In addition to the mass numbers and abundant varieties of these energy savings promoters, there have been an equal number of energy audit articles written for the engineering magazines. And to one’s wonderful delight, most of the articles (thanks to the due diligence and back-up research of the publishers) have been an excellent resource on how to save energy in your 4 billion-square-foot manufacturing facility.

Big energy audits usually save big energy, but they cost big bucks. Where does this leave the little guy, and how do these magazine articles come into play? Well, the little guy usually operates a 15 – 75 horsepower air compressor and if he (or she) read these articles, many of them will gain the appropriate knowledge to cash-in on similar energy saving opportunities.

The fact is energy audits, like companies, come in all shapes and sizes. The Compressed Air Challenge® website, http://www.compressedairchallenge.org/, is another great resource for anyone interested in saving energy. Check out the “Library” section for specific compressed air energy saving tips. A key element when considering an audit is that they should be performed when the systems are running normally and there is no need for any downtime.

Walk the line

This is the simplest of all procedures and can be characterized by the fact that no hardware is involved. A Walk the Line audit involves a visual check, done inside and outside of the compressor room. Atlas Copco has a comprehensive 10-point check list for its walk the line appointments, inspecting things such as filters, piping structure and condensate drains. Many of the issues that compromise a compressed air system’s performance are often as rudimentary as identifying and sealing leaks and decreasing pressure drops through reconfigured piping and system analysis to ensure that the facility has the right compressor for the job. A walk the line audit is also a great opportunity to learn more about available alternatives, like Variable Speed Drive compressors, and how they match a facility’s fluctuating energy demands.

These no-cost compressed air system health checks are often available from compressor manufacturers at no charge. The primary objective is to optimize the performance of a facility’s compressed air system to help the operator save money through more cost-effective and efficient operations.

Demands on a compressed air system vary to reflect every corresponding change to a manufacturing or process adjustment within the facility. A walk the line energy audit can help provide a brief assessment of the current productivity levels and suggest changes to maximize efficiency or provide in-depth analysis of various components, depending on the manufacturer’s primary objectives. Any one or several of Atlas Copco’s Top 10 Tips to maximize efficiency could be employed to address weaknesses in the compressed air system. Results also can be prioritized to show how potential savings match up with the necessary expenditures.

Data logging

Along with a visual check like that from a Walk the Line audit, this audit involves data logging of the current (Amps). By using a standard formula (one that includes power factor), the kW can be calculated to a reasonably accurate value and graphs illustrating demand can be included.

The following examples are from a less comprehensive audit, but provide good examples of what is available and what can be achieved. The audit needs to start somewhere – why not start in the compressor room where the compressed air originates? The duration of the audit (data logging) should be a minimum of seven days, so it always includes a weekend.

Another key consideration when choosing an audit partner would be to ask about the potential rebates available from the local utility companies. People who are close to the subject and do this every day know these facts (as all programs are a little different) and these savings can really add up.

A block diagram of the supply side will help identify what is in the compressor room, if it is a sufficient scope of supply and if it is set up correctly. You should also do a walk-through of the plant floor and observe the compressed air piping layout, the machinery or pneumatic tools that will be consuming the compressed air and look for any possible inappropriate uses, such as open hose nozzles or using expensive compressed air for personal cooling (as opposed to a small fan).

The example below is an actual customer that used a 20 horsepower air compressor system in a small New England town. The air compressor is a Load/No-Load controlled product and has a CT loop (current transformer) data logger attached to an incoming motor lead. This allows data logging of the current (Amps) and by using a standard formula (one that includes power factor) the kW can be calculated to a reasonably accurate value.

However, it is still very important to take a baseline reading of Amps and Voltage before you start the audit, including the Full Load values and the Un-Loaded values, which will help determine and confirm the accuracy (and integrity) of the final report values. Also, make sure that the production line is operating normally during the audit duration. The seven-day audit will be the guideline for a normal week of production and will be used for an annual energy cost calculation.

What is additionally important is that we can easily record a Load/No-Load compressed air outlet profile and determine if the unit is correctly sized or if it is ‘close to’ its maximum capable CFM output.

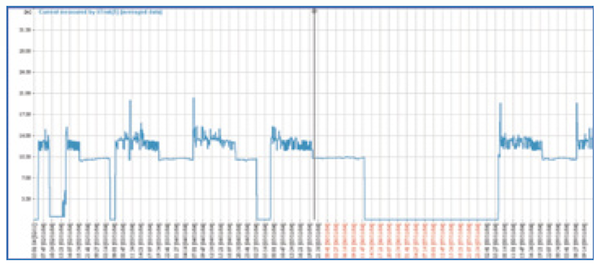

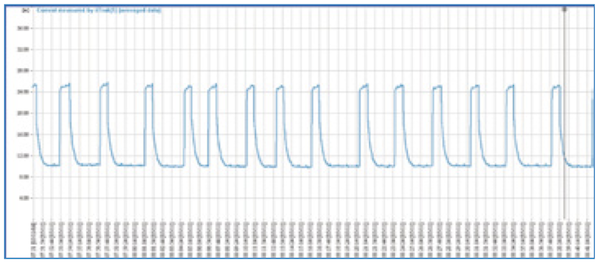

Referencing the above installation and the recorded profiles below (Fig-1, 2, 3) we can see that this unit is quite oversized for the application. We find many installations are like this, mostly due to the diminishing economy and reduction in manufacturing’s use of compressed air.

This is a profile of the complete week, where the Amps are recorded at one second intervals for the seven days. The software indicates a day-to-day profile (in black numbers) and the weekend is also shown (in red numbers).

As we magnify further into the profile we can see that this unit is cycling frequently. One reason for this is that the unit is oversized for the application. The compressor is running fully loaded for very short periods and running un-loaded (idling) for very long periods.

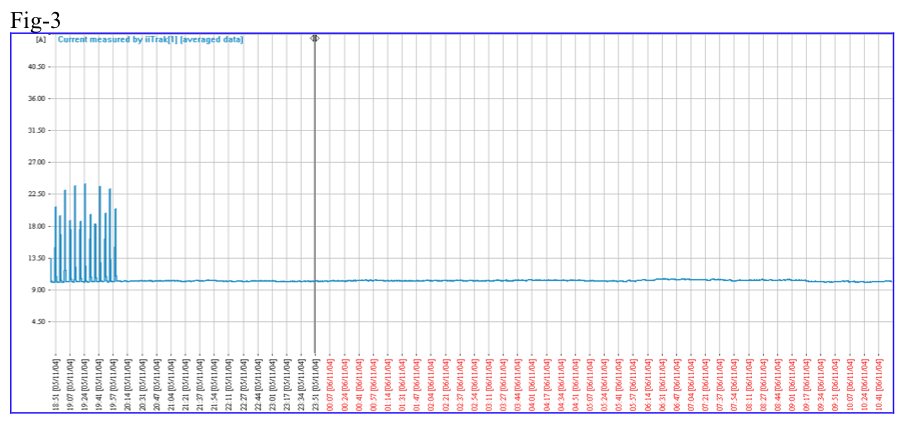

When we review the weekend data, (the red numbers) we can see a very steady use of air.

Although the customer does not work on the weekend, we asked them to leave the air compressor in auto-start mode during a period with no production. When no one in production is using compressed air, this can be identified as compressed air leaks. Once this is known, a more accurate leak detection audit can be performed. We would not include the weekend profile when calculating demand, but this gives us a great indication of the artificial demand (leaks).

The point of offering these smaller audits is to detect energy waste and capture a compressed air profile of the Supply Side – the compressor room. By analyzing the supply side we can then promote the need to evaluate the issues on the demand side. The initial set up and process is very simple, but what is most important, is that it allows us the opportunity and proof that further analysis may be required.

The savings?

Sure the units and energy loss are smaller, but there are literally millions of smaller air compressors in the field. Again, even “smaller company” compressor owners can save money, and a \$1,000 savings is big bucks to them.

AirScan (Full Audits)

A variety of options are available with the AirScan audit, ranging from full system audits to specific measurements, such as leak detection, power and flow rate, etc. AirScan is a flexible, diagnostic package for compressed air systems that allows customers to select any level of air audit required for their particular system.

Options for the AirScan audit include:

Audits for everyone?

Now, are inexpensive compressed air audits available? Of course, but as with the more comprehensive studies, be cautious of how they are performed and by whom. Here are a few good questions to ask before an audit:

We mentioned the importance of running a weekend study earlier. Even though production may not operate on the weekend, the importance of data logging those days can be significant. Figure 5 is from a software program which allows the audit technician to simulate the CFM consumption, which is converted from the Amp study. Remember, this is fairly easy with Load/No-load air compressors. When the inlet throttle is open you are making compressed air and when it is closed you are not.

If a unit (as in Fig-5) is operating for long periods of time ‘unloaded’ it is similar to sitting in your car at a red light with the engine running (in some cases for several hours). Just like in your car, you are wasting energy when your compressor is idling. (A subject for another day, but we previously mentioned Variable Speed Drive air compressors. Considered the Hybrids of the industry, VSD compressors actually ‘stop running’ ‘when they come to the red light.’)

The black and fuchsia colored lines represent the weekend study. Production was not operating; the units were run so a profile could be created to show suspect air leaks. As we see in fig-5 this facility had lots of air leaks and they were not sure how many or how much CFM was being wasted until we ran the audit. The follow up air leak detection study proved to be very beneficial. Several corrections were made and the customer is now saving thousands of dollars.

Summary

Companies may be hesitant to spend a lot of money on energy audits, especially when they have little understanding of the true possible savings. The objective is to help them understand the importance and the benefits of an audit; not only will they lower energy costs, but their production lines will operate more efficiently as well.

We have only discussed Load/No-Load air compressors within this article, there are many other air compressors with less efficient control systems where even more savings can be achieved. And don’t forget the Demand Side, this is where the corrections need to be made to cash-in on the real savings. All of the previously discussed information is directly related to initial base-load information and integrity of the analyzed data.

Our point was to answer the question: Are Compressed Air Audits viable for everyone? Our answer is a resounding, “Yes.” By adjusting the audit scope to meet your needs you can save big bucks, whether you operate a 4 billion-square-foot facility or much smaller operation.

About the Author

Bob Baker, a sales & marketing training manager at Atlas Copco, has extensive experience as an energy auditor and systems manager. Bob has performed countless energy audits for customers across the United States.